[fusion_builder_container hundred_percent=”no” equal_height_columns=”no” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” background_position=”center center” background_repeat=”no-repeat” fade=”no” background_parallax=”none” enable_mobile=”no” parallax_speed=”0.3″ video_aspect_ratio=”16:9″ video_loop=”yes” video_mute=”yes” border_style=”solid” type=”flex”][fusion_builder_row][fusion_builder_column type=”1_1″ layout=”1_1″ spacing=”yes” center_content=”no” hover_type=”none” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” background_position=”left top” background_repeat=”no-repeat” border_style=”solid” border_position=”all” margin_top=”0px” margin_bottom=”0px” animation_direction=”left” animation_speed=”0.3″ last=”true” first=”true” background_blend_mode=”overlay” min_height=”” link=””][fusion_text hide_on_mobile=”small-visibility,medium-visibility,large-visibility” sticky_display=”normal,sticky” animation_direction=”left” animation_speed=”0.3″ animation_delay=”0″ columns=”1″]

Halo, sahabat! Pernahkah Anda mendengar tentang faktor keselamatan industri? Dalam dunia industri, faktor keselamatan memiliki peran yang sangat penting dalam berbagai proses. Pengukuran dan faktor keselamatan pada line produksi yang menggunakan bahan bakar gas sangat penting untuk memastikan operasi yang efisien dan aman. Berikut adalah panduan untuk pengukuran serta langkah-langkah yang harus diambil untuk memastikan faktor keselamatan pada sistem gas:

1. Pengukuran pada Sistem Gas

a. Pengukuran Tekanan

- Pressure Gauge (Pengukur Tekanan): Gunakan pressure gauge untuk memantau tekanan gas di berbagai titik dalam sistem, seperti sebelum dan sesudah regulator serta di titik-titik kritis lainnya.

- Kalibrasi: Pastikan pressure gauge dikalibrasi secara teratur untuk memastikan akurasi. Periksa apakah pengukur tekanan sesuai dengan spesifikasi pabrikan dan tidak menunjukkan pembacaan yang salah.

b. Pengukuran Aliran

- Flow Meter (Pengukur Aliran): Gunakan flow meter untuk mengukur aliran gas dalam sistem. Ini penting untuk memastikan bahwa jumlah gas yang digunakan sesuai dengan kebutuhan produksi.

- Kalibrasi: Kalibrasi flow meter secara berkala untuk memastikan akurasi pengukuran aliran.

c. Pengukuran Temperatur

- Temperature Sensor (Sensor Suhu): Gunakan sensor suhu untuk memantau suhu gas, terutama jika gas mengalami pemanasan atau pendinginan selama proses.

- Kalibrasi: Kalibrasi sensor suhu sesuai dengan rentang suhu yang relevan untuk sistem gas.

d. Pengukuran Kualitas Gas

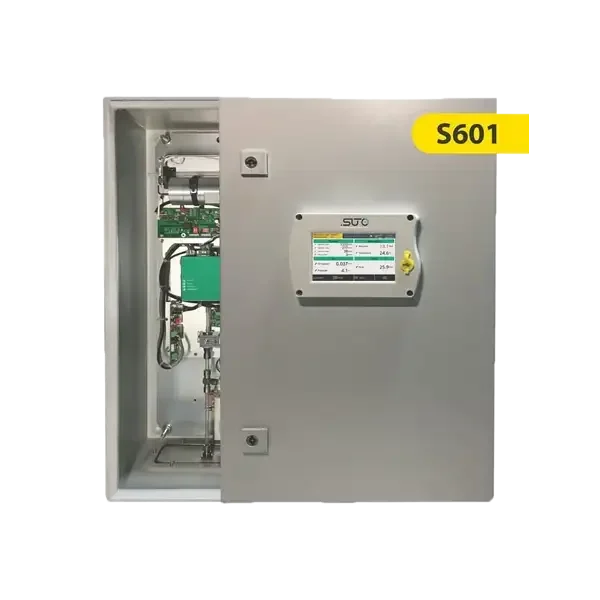

- Gas Analyzer (Analisa Gas): Gunakan alat analisa gas untuk memeriksa komposisi gas dan memastikan bahwa kualitas gas sesuai dengan spesifikasi yang diperlukan.

[/fusion_text][fusion_imageframe aspect_ratio=”2-1″ custom_aspect_ratio=”100″ aspect_ratio_position=”41% 32%” lightbox=”no” linktarget=”_self” align_medium=”none” align_small=”none” align=”none” mask=”” custom_mask=”” mask_size=”” mask_custom_size=”” mask_position=”” mask_custom_position=”” mask_repeat=”” style_type=”” hover_type=”none” magnify_duration=”120″ scroll_height=”100″ scroll_speed=”1″ margin_medium=”” margin_small=”” caption_style=”off” caption_align_medium=”none” caption_align_small=”none” caption_align=”none” caption_title_tag=”2″ animation_direction=”left” animation_color=”” animation_speed=”0.3″ animation_delay=”0″ hide_on_mobile=”small-visibility,medium-visibility,large-visibility” sticky_display=”normal,sticky” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″ image_id=”22897|full”]https://lyntex.id/wp-content/uploads/2024/09/WhatsApp-Image-2024-03-23-at-3.09.28-PM-1.jpeg[/fusion_imageframe][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container][fusion_builder_container hundred_percent=”yes” overflow=”visible” margin_top=”5px” type=”flex”][fusion_builder_row][fusion_builder_column type=”1_1″ layout=”1_1″ background_position=”left top” border_style=”solid” spacing=”yes” background_repeat=”no-repeat” margin_top=”0px” margin_bottom=”0px” animation_speed=”0.3″ animation_direction=”left” hide_on_mobile=”no” center_content=”no” min_height=”none” last=”true” hover_type=”none” border_position=”all” align_self=”flex-start” first=”true” background_blend_mode=”overlay” link=””][fusion_separator style_type=”none” alignment=”center” /][fusion_text font_size=”30px” fusion_font_variant_text_font=”400″]

Baca Juga : Mengenal Boiler Industri: Manfaat dan Jenis Type Boiler Merk Miura

[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container][fusion_builder_container hundred_percent=”yes” overflow=”visible” margin_top=”20px” type=”flex”][fusion_builder_row][fusion_builder_column type=”1_1″ layout=”1_1″ background_position=”left top” border_style=”solid” spacing=”yes” background_repeat=”no-repeat” margin_top=”0px” margin_bottom=”0px” animation_speed=”0.3″ animation_direction=”left” hide_on_mobile=”no” center_content=”no” min_height=”none” last=”true” hover_type=”none” border_position=”all” align_self=”flex-start” first=”true” background_blend_mode=”overlay” link=””][fusion_separator style_type=”none” alignment=”center” /][fusion_text hide_on_mobile=”small-visibility,medium-visibility,large-visibility” sticky_display=”normal,sticky” animation_direction=”left” animation_speed=”0.3″ animation_delay=”0″]

[/fusion_text][fusion_imageframe image_id=”22896|full” aspect_ratio=”3-2″ custom_aspect_ratio=”100″ aspect_ratio_position=”48% 6%” skip_lazy_load=”” lightbox=”no” gallery_id=”” lightbox_image=”” lightbox_image_id=”” alt=”” link=”https://lyntex.id/boiler-steam/” linktarget=”_self” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” sticky_display=”normal,sticky” class=”” id=”” max_width=”” sticky_max_width=”” align_medium=”none” align_small=”none” align=”center” mask=”” custom_mask=”” mask_size=”” mask_custom_size=”” mask_position=”” mask_custom_position=”” mask_repeat=”” style_type=”” blur=”” stylecolor=”” hue=”” saturation=”” lightness=”” alpha=”” hover_type=”none” magnify_full_img=”” magnify_duration=”120″ scroll_height=”100″ scroll_speed=”1″ margin_top_medium=”” margin_right_medium=”” margin_bottom_medium=”” margin_left_medium=”” margin_top_small=”” margin_right_small=”” margin_bottom_small=”” margin_left_small=”” margin_top=”” margin_right=”” margin_bottom=”” margin_left=”” bordersize=”” bordercolor=”” borderradius=”” z_index=”” caption_style=”off” caption_align_medium=”none” caption_align_small=”none” caption_align=”none” caption_title=”” caption_text=”” caption_title_tag=”2″ fusion_font_family_caption_title_font=”” fusion_font_variant_caption_title_font=”” caption_title_size=”” caption_title_line_height=”” caption_title_letter_spacing=”” caption_title_transform=”” caption_title_color=”” caption_background_color=”” fusion_font_family_caption_text_font=”” fusion_font_variant_caption_text_font=”” caption_text_size=”” caption_text_line_height=”” caption_text_letter_spacing=”” caption_text_transform=”” caption_text_color=”” caption_border_color=”” caption_overlay_color=”” caption_margin_top=”” caption_margin_right=”” caption_margin_bottom=”” caption_margin_left=”” animation_type=”” animation_direction=”left” animation_color=”” animation_speed=”0.3″ animation_delay=”0″ animation_offset=”” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″]https://lyntex.id/wp-content/uploads/2024/09/2.png[/fusion_imageframe][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]